--The Main Factors Affecting Reflective Brightness in Road Traffic Signs and Countermeasures

With the rapid development of highway and urban construction, the highway traffic flow is increasing day by day, which brings great pressure to highway traffic management and traffic safety. With the increasing traffic volume, how to add traffic signs and improve road traffic safety facilities has always been an important link in traffic management.

Traffic signs require reflective film as surface material. How to use reflective film reasonably is of great practical significance to improve the safe sight distance, reduce the occurrence of road traffic accidents, save people's lives and property, save energy and reduce emissions, and protect the environment.

1. Requirements of traffic signs for reflective films

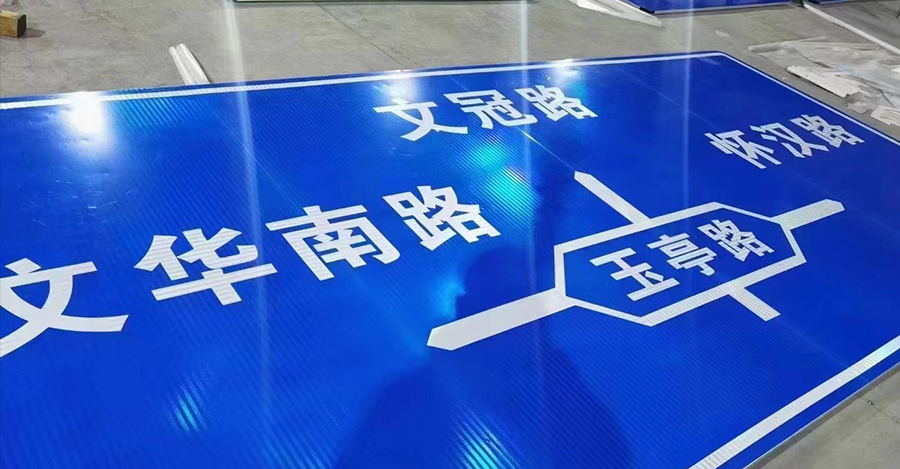

Road traffic signs use graphic symbols and characters to convey specific information, and their shape, color, size, pattern type and location are clearly stipulated in Road Traffic Signs and Marking. In the design specifications of road traffic signs at all levels in China, it is also clearly stated that in principle, reflective materials must be used to make signs.

2. The main factors affecting the reflective brightness

(1)The quality of reflective film is not up to standard

Reflective film is a special structural material that reflects light back to the light source. The use of reflective film, its quality must meet the due standards.

(2) The reflective signboard is uneven or contaminated by impurities, which makes the reflected light scattered.

The production of reflective signs includes two parts: board structure processing and board pasting. First of all, the processing quality of the board will affect the subsequent board pasting, so the processing of the board must meet the standard. In addition, if there are obvious bubbles and wrinkles on the reflective film pasted on the board, it will damage the reflective film to a certain extent, and the impurity pollution on the board will also cause uneven color of the reflective film. Reflective signs with these problems will not only affect the appearance, but also cause the reflective film to fall off and indicate unclear in serious cases.

3. The installation of reflective signs has the problem of improper angle.

There are many changes in highway traffic routes, so it is necessary to scientifically design the installation of reflective signs according to the actual needs and the specific performance of reflective films, so as to improve the observation effect of important observation points on reflective signs in driving routes.

3. Countermeasures and measures taken

(1) Adopt reflective film products with reliable quality and meeting the requirements.

Adopt reflective film products with reliable quality and meeting the requirements to ensure that the reflective film can maintain sufficient visibility in the whole life cycle. The grade of reflective film should be consistent with the design regulations. Engineering-grade or economical reflective films are mostly used in urban and rural low-grade roads; National high-grade highways mostly use super-grade and above reflective films that meet national standards.

(2) Ensure the processing quality of the sign board.

In addition to the reflective film itself, the important factors that affect the reflectivity of reflective signs include the processing quality of the sign board surface, so the processing quality of the sign board surface must be strictly controlled, including keeping the board surface flat and the cutting edge smooth when cutting and blanking the board surface. During the welding and riveting of the board surface, it shall be firm and firm, and shall not be loose, etc.

(3) Ensure the pasting quality of the reflective film of the signboard.

Different types of reflective films have different pasting methods. For example, the pressure-sensitive reflective film should adopt continuous electric rolling laminating machine, hand laminating machine or manual laminating machine; The heat-sensitive reflective film adopts vacuum heat-sensitive pressing and other methods.

No matter what method is used, attention should be paid to: ensure that the corner of the reflective film does not crack or tear off; check whether there are bubbles during or after pasting, and if bubbles are found, deal with them in time to avoid the phenomenon that the bubbles become bigger after long-term use, which will lead to poor pasting.

END

In order to ensure the visibility of traffic signs under poor visibility conditions, it is necessary to use a large number of reflective film materials in road traffic signs. In specific applications, it is necessary to strictly control the quality of materials and the control of processing and production, eliminate all kinds of adverse factors affecting the quality, and better meet the needs of road traffic development. The better the retroreflective performance of traffic signs, the better the road traffic safety effect.